04 Sep The Durian Packaging Guide: Keeping The King Fresh

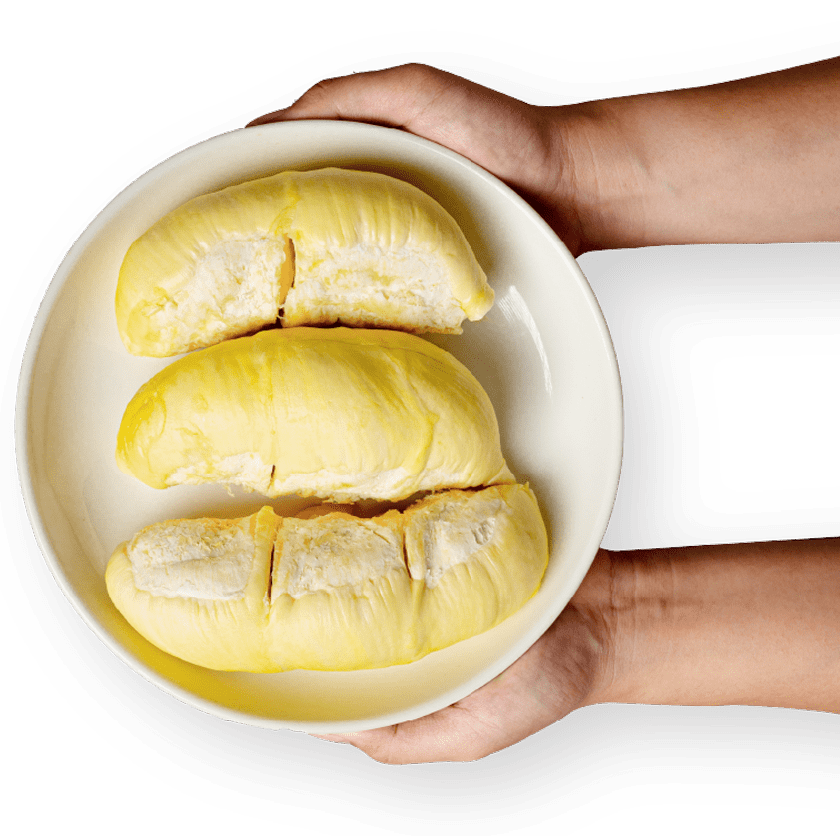

Durian, often dubbed the “King of Fruits”, is a delicacy cherished in Southeast Asia and increasingly popular in markets like China and Hong Kong.

Its spiky exterior, pungent aroma, and unique flavor make it a sought-after fruit globally, but its packaging is a challenge for exportation.

This guide simplifies the process of durian packaging, exploring the best methods to preserve freshness and quality while minimizing waste.

Learn how effective packaging can protect your durian.

How Freshly Harvested Durian are Processed and Packed

It begins at the harvesting stage, where fully matured fruits are collected after naturally falling from the tree.

The fruits are then carefully selected based on size, weight, and the absence of defects.

After thorough washing and air drying to remove dirt and prevent mold, durians are sorted and graded by size, ripeness, and quality.

This grading helps determine the best packaging method and target market.

Differences in Packing for Local Delivery and Export

Top Fruits implements strict quality control measures for its durian products to maintain peak freshness and quality by undergoing meticulous inspection, de-husking, and vacuum-sealing for preservation.

For local delivery, wrap whole durians and place them in durable, ventilated boxes or crates.

De-husked durians should be vacuum-sealed or stored in airtight containers with insulation.

This is followed by quick transportation to designated locations to maintain freshness.

For export, wrap frozen durians and pack them in ventilated cardboard boxes.

De-husked durians should be vacuum-sealed, flash-frozen, and stored in insulated boxes with gel packs or dry ice to maintain the cold chain.

Then, all customs documentation for cargo must be completed.

The processes are complex, but the results of delivering high-quality products are rewarding.

Before venturing into the durian business, we recommend conducting thorough research, understanding market dynamics, identifying reliable suppliers or growing conditions, and developing a comprehensive business strategy.

Best Packaging Methods to Maintain Durian Freshness

At Top Fruits, we manage the entire journey of durian—from planting the seeds to packaging the fruit—with utmost care to ensure the durians remain in top condition.

Thus, proper packaging plays a crucial role in maintaining durian freshness.

Two commonly used machines for flash-freezing durians are the IQF liquid nitrogen tunnel freezer and the cryogenic freezer chamber.

Both machines are designed to achieve rapid freezing, reducing the temperature to between -80°C and -100°C, or even lower, within approximately one hour.

After freezing, durians are stored at -18°C to keep their quality intact and extend their shelf life up to 18 months.

We understand how crucial it is to maintain the fruit’s natural freshness as it travels from the plantation to the consumer.

So, we choose the best packaging methods that help preserve the rich flavor and aroma of durians, ensuring they reach our customers just as nature intended.

Types of Vacuum Packaging: The Whole Frozen Durian and Pulp

Durian packaging has been revolutionized to keep up with the growing demand globally.

At Top Fruits, we utilize smart farming and advanced vacuum packaging techniques to offer whole frozen durians and packaged pulp at peak freshness.

Here are a few machines commonly used

| Machine | Pros | Cons |

|---|---|---|

| Double Chamber Vacuum Sealer. | Suitable for massive production output. Deep cavity for packing large items. Low-cost It can be used to pack whole frozen durians and durians’ pulp. | Rust in 1-2 years Large in size. Not suitable for small or limited space areas. Need separate vacuum bags. |

| Thermoforming Vacuum Packaging (MAP/Vacuum Skin Packaging) | Ideal for high-volume production. It can handle both flexible and rigid films, ideal for a diverse range of shapes. Comes in semi-automatic and fully automatic. Reduce labor costs. Precise film usage and efficient packaging result in less waste. It can be used for whole frozen durians and durians’ pulp. | High-cost, quite pricey for a small or medium-sized business. Compatible with certain types of film material only. A professional operator is needed to maneuver the machine. It is not ideal for small or confined spaces. |

| Vacuum Skin Packaging (VSP) | Suitable for small- or medium-sized companies. Affordable and budget-friendly. Available in both semi-automatic and fully automatic versions. Reduce labor costs. The most suitable for commercial use. Customizable according to the shape of the container. | Due to fixed and customized mold, the machine can only pack specific product sizes. A professional operator is needed. It's not suitable to pack a whole durian. A higher budget is required for better quality machines that produce high output. |

It’s essential to take the time to research and consider your options carefully, so you can confidently make the right choice.

Thus, there are many factors to consider when purchasing packaging machines for your company.

At Top Fruits, we manufacture fresh and frozen durian as well as research and develop durian-based products and services. This requires us to use and manage various packaging machines.

Understanding what works best can vary depending on many factors. We will explore six tips for choosing the right packaging machine.

- Evaluate Machine Capacity: Consider the volume of durians you need to package.

Choose a machine with a capacity that matches your production scale to ensure efficiency and avoid bottlenecks. - Consider Ease of Maintenance: Opt for machines that are easy to clean and maintain.

Durian packaging can be messy, so machines that are easy to disassemble and clean can save time and reduce downtime. - Assess Reliability and Durability: Invest in machines from reputable manufacturers known for their reliability and durability.

High-quality machines tend to have longer lifespans and fewer issues. - Check for Compliance: Verify that the machine complies with industry standards and food safety and packaging regulations.

- Compare Costs: Consider the total cost of ownership, including initial purchase price, operating costs, and potential maintenance expenses.

Choose a machine that provides the best value for your investment. - Seek or Consult a Qualified Expert: Get advice from industry experts who can provide reliable and effective insights to aid your decision-making.

If you are looking for all-rounded advice, Top Fruits is your ideal option.

We specialize in consultancy services encompassing all facets of the durian industry, including durian plantation management and development, ensuring you have the support you need to succeed—contact us today to learn more.

Interested to venture into durian farming? Discover how we grow our client’s durian farming business here : Case Study: How Top Fruits Grew a Pahang Durian Business.

Industrial-Grade Materials Used for Durian’s Packaging

While packaging machines have seen significant technological advancements, the materials used in the process have also evolved to meet the demands of modern packaging machines, developed to protect and preserve products better.

Pre-made Nylon LDPE Vacuum Bag

Pre-made Nylon LDPE vacuum bags are ideal for packaging whole frozen durians.

The nylon provides strong puncture resistance, perfect for handling durian’s sharp spikes, while the LDPE layer ensures a flexible, airtight seal.

These bags protect the durian from moisture loss, freezer burn, and contaminants, preserving its flavor and freshness during freezing and transport.

Skin Pack Film:

Skin pack films such as polyethylene-based are transparent, soft, durable, and flexible, allowing them to conform to products of various shapes and sizes while maintaining a clear view of the contents.

These films are typically used in vacuum skin packaging machines, where their adaptability ensures a tight, secure seal over the product, making them ideal for preserving and displaying a wide range of items.

CPET Skin Pack Trays (Crystalline Polyethylene Terephthalate):

CPET trays are known for their durability, heat resistance, and microwave-safe properties, making them an excellent choice for vacuum skin packaging, especially for ready-to-eat meals.

These trays are commonly used with VSP machines that cater to products requiring safe reheating. The trays maintain their structural integrity during the packaging and reheating.

PP Skin Pack Trays (Polypropylene):

Polypropylene (PP) skin trays are more flexible than CPET trays, providing versatility in packaging fresh and pre-cooked foods.

These trays are widely used in vacuum skin packaging machines that handle various food products requiring adaptable packaging solutions.

The flexibility of PP trays ensures that the packaging can accommodate items of different shapes and sizes without compromising the seal.

Paperboard:

Laminated paperboard is increasingly popular in vacuum skin packaging (VSP) due to its enhanced merchandising appeal, presentation, and reduced plastic usage.

This material is especially favored for packaging cheeses, fish, and other meats and is compatible with VSP machines designed to work with paperboard substrates.

Thermoforming Film:

Thermoforming films are durable, stretchable, and adaptable to various product shapes during the packaging process.

These films are primarily used in thermoforming vacuum packaging machines, which heat and mold the film around the product to create a tight, secure seal.

The films play a critical role in preserving the freshness and quality of the packaged product, making them essential for food items that require a longer shelf life.

Conclusion

Durian packaging is a meticulous process that begins with careful harvesting and ends with innovative packaging techniques designed to preserve freshness and quality.

For local delivery or export, selecting suitable packaging methods and machines is crucial for maintaining the fruit’s integrity.

The industry also shows potential in shifting to sustainable solutions, such as biodegradable packaging made from durian rind, which holds promise for reducing negative environmental impact.

Top Fruits’ expertise in packaging and consultancy ensures that durians reach consumers in optimal condition, reflecting a commitment to quality and innovation.

FAQ

How much does a durian packaging machine cost?

The cost of a durian packaging machine can vary widely depending on several factors, including the type of machine, its capacity, features, and the manufacturer.

Here’s a rough estimate of what you might expect:

Entry-Level Packaging Machines: For basic, manual prices typically range from RM3500 to RM43,000. As for semi-automatic machines, These machines usually handle basic tasks such as sealing, wrapping, and cutting.

Fully Automatic Machines: Advanced, fully automatic machines that handle high volumes and offer features like automated filling, sealing, and labeling can cost between RM129,000 and RM370,000 or more.

Custom Solutions: Customized or specialized machines, which may include advanced features or tailored designs for specific packaging needs, can exceed more than RM100,000.

Can vacuum-packed durians be brought on flight?

Unfortunately, for domestic flights, even if the fruit is tightly sealed or vacuum-sealed. Durian and other strongly-smelling fruits that are universally prohibited in aircraft cabins are also banned from being carried in checked luggage.

However, durians can be exported by air cargo for international shipping, and strict conditions are required to prevent leakage:

- Durian fruits must go through flash freezing first.

- Place frozen durian fruits into an expanded polystyrene foam box.

- Place an Ice gel on top of the wrapped fruits (to note, this is optional)

- Seal the expanded polystyrene foam box.

- Wrap the expanded polystyrene foam box with shrinking film.

Learn more with this article.