20 Mar Durian Harvesting: A Comprehensive Guide

As the “King of Fruits” in Malaysia, durian holds a special place in the hearts and palates of many.

However, did you know that the journey of this beloved fruit from the tree to your table involves intricate processes?

Today, let’s delve into the art of durian harvesting, exploring everything from identifying ripeness to post-harvest practices and transportation!

Identifying Ripeness

The process of durian harvesting starts with identifying the ripeness of durians. Below are the maturity indices of durians in general:

- Bulging abscission zone

The abscission zone of a durian is the area or point where the durian fruit stem naturally detaches from the branch.

As durians mature, their abscission zone will swell, causing them to fall from the tree. - Green thorns with brown tips

When durians mature, their spike tips turn yellowish brown, unlike the bright green hue of immature durians or the dark brown hue of overripe durians. However, light intensity can impact these colors. - Pliable spines

Mature durians have pliable spine tips that can be pulled together by the fingers more easily than those of immature fruit. - Distinct carpel sutures

The carpel sutures of mature durians can be seen very clearly even if they are located at higher branches. - Produces a dull, hollow sound when tapped

When a knife, fingertip or wooden stick is run through or knocked on fruit spines, mature durians sound dull and hollow. If durians are still immature, they will sound solid - Strong Odor

Durians close to ripening or already ripe exude a pungent, distinct odor. However, durians harvested at this stage are unsuitable for long-distance transportation or extended storage.

Harvesting Durians

The main durian season in Malaysia typically spans from May or June through August or September, with the peak occurring during July and August.

The second season, which has fewer varieties, usually starts in October or November until January or February.

During this time, the main method employed in Malaysia for durian harvesting was to allow ripe durians to drop naturally from the tree onto the ground.

To ensure durian farmers can collect the fallen durians immediately, they:

- Build grass huts near the durian trees and camp there for 6 to 8 weeks.

- Install big nets underneath the durian trees to hold the fallen durians.

- Deploy workers to climb and tie the strings to the durians’ stems. When the durian ripens and drops, it will not hit the ground and damage the durian’s thorns.

At the beginning and end of the durian harvesting season, durians are typically collected only once per day, as the yield is relatively low during this period.

However, a twice-a-day collection schedule (morning and evening) will be employed as the fruiting season peaks. During this period, durians may drop either during the day or throughout the night.

Caution: Be aware of falling durians, which can cause serious injury.

Post Harvesting

After harvesting the durians, they must undergo a series of post-harvesting processes before reaching your hands.

These processes play a vital role in preserving the durian’s flavor and quality. Let’s take a look at those processes now!

In-Field Handling

Harvested durians are rapidly transported to the collection center to be further sorted out.

In small orchards, the durians are carried manually, on bicycles, or motorcycles. For bigger orchards or plantations, lorries or tractor-mounted trailers are commonly employed for in-field transport.

Remarkably, durians are not suitable for rough transportation. This will cause the spiky durians to rub against each other inside the containers, leading to broken durian spines and leaving them prone to infection by pathogens.

Sorting

Once the durians arrive at the collection center, they will be sorted according to size, maturity, cultivars, degree of damage and cleanliness.

In this stage, durians with blemishes, those infected with disease, damaged by rodents or insects, and other imperfections will be set aside for immediate consumption, processing or discarding.

Meanwhile, the durians without any defects will proceed to subsequent processes.

Cleaning

After sorting, the selected durians will be cleaned using special brushes or air guns to remove the unwanted materials adhering to them, such as debris, dirt, soil, leaf remnants, branches and cobwebs.

It is advised not to wash durians, as added moisture can speed up their spoilage.

Grading

Currently, Malaysia does not have a standardized grading system for durians. The criteria for grading and pricing durian fruits are based on negotiations between durian farmers and traders.

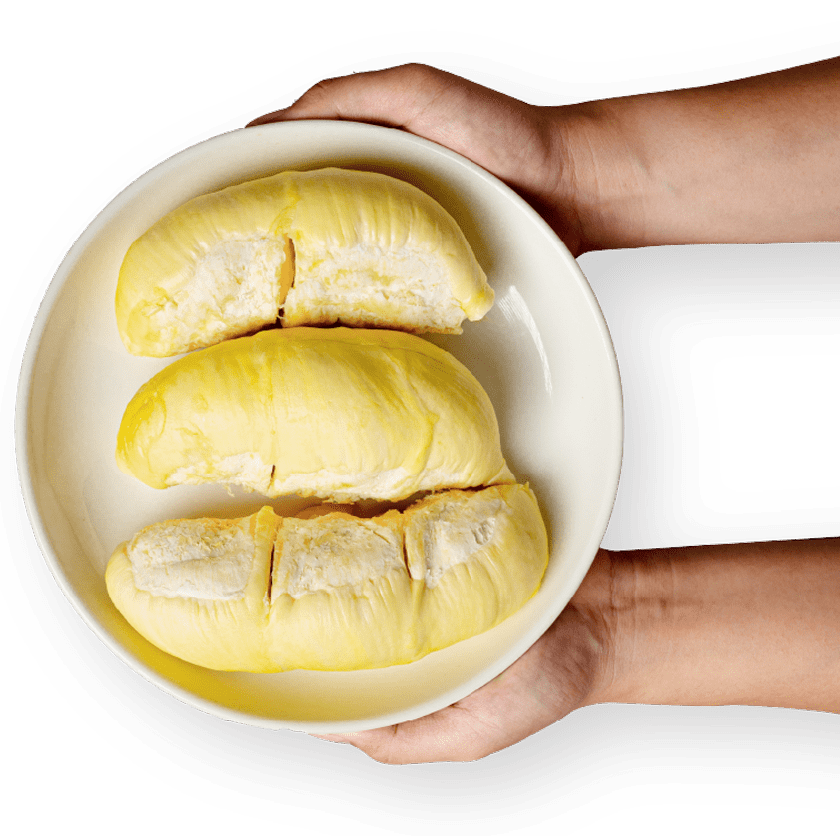

However, the rule of thumb for an ideal durian is:

- Has a rich aroma.

- Has a silky-smooth flesh texture.

- Has succulent yet firm flesh.

- Has a perfect balance of bitterness and sweetness in its flavor.

Packing

Packing is essential in preparing the durians for safe transportation and marketing while protecting their quality. Typically, durians are packed in bamboo baskets and wooden crates.

Bamboo baskets are usually employed for short-distance transportation, such as transporting to local or nearby markets. These baskets provide better ventilation to maintain the durians’ quality and are more cost-effective.

However, bamboo baskets are not rigid enough to allow stacking during storage and transportation. If a second layer is needed, workers will place the next tier of baskets on a simple platform.

On the other hand, wooden crates provide better protection and are sturdy enough to allow stacking, making them the suitable packaging material for durians intended for distant markets.

Durians are often arranged in single layers to prevent compression and mechanical damage.

If stacking durians on top of each other in transport vehicles cannot be avoided, the layers of durians should be separated using pieces of cardboard to offer protection against punctures from spines and compaction damage.

Sometimes, they are also wrapped in protective materials such as newspapers and banana leaves. This prevents their exposure to excessive moisture or air, which could accelerate the ripening process and compromise their quality.

Storing

If left at room temperature, durians can only last for 2-3 days after harvesting. Hence, proper storage is crucial to extend their marketable period and preserve quality.

Here are some of the ways to store durians:

- Cold Storage / RefrigerationDurians kept in cold rooms or refrigerated containers at 10-15°C with 85-90% relative humidity can extend their shelf life to around 2 weeks (this varies depending on the cultivar and form of durian).However, please be aware that durians chilled below their optimum temperature may lead to chilling injury and alter their flavor.

- Cryogenic FreezingAfter harvesting, fresh durian fruits can be rapidly frozen by exposing them to liquid nitrogen at around -110°C to -90°C for 60 to 90 minutes. The frozen fruits can then be stored at -18°C for 2 years while retaining their original flavor, taste, flesh color and texture.

- Vacuum PackagingThis method involves the removal of air from the packaging before sealing. Durian flesh stored in this way can extend its shelf life for up to 1 year.

- Modified Atmosphere Packaging (MAP)In this method, durian flesh is placed into plastic trays and flushed with a specific gaseous mixture which typically comprises 3-5% oxygen, 5-15% carbon dioxide and nitrogen.After sealing the trays containing the durian flesh and specific gaseous mixture, they are stored under refrigerated conditions, extending their shelf lives to up to 8 weeks.

These storage methods enable both locals and people worldwide to enjoy durians year-round, leading to increased global demand for durians and the rising potential for lucrative investment in durian cultivation.

Transportation

Source: The Jakarta Post

There are several transportation modes for durians, depending on the delivery distance and the required speed.

For local or domestic transportation, durians are typically transported by trucks, lorries or vans over roads.

During transportation, these vehicles are covered with tarps or canvas to prevent the durians from being exposed to direct sunlight, as these highly perishable fruits may crack when exposed to sunlight.

Ideally, transportation should also be done at a cooler time of the day, preferably at night, to prevent heat build-up within the containers and affect the quality of durians.

For export or long distances, durians may be transported via ships, airplanes or trains.

To preserve the durians’ quality during transportation over long distances, these vehicles are equipped with specialized insulated and temperature-controlled containers to maintain the ideal temperature and humidity levels for durians.

Unlock the Secrets of Durian Planting with Top Fruits

While durian harvesting is undoubtedly a skilled and labor-intensive process, cultivating these beloved “Kings of Fruits” is also intricate and time-consuming.

Rather than navigating the complex world of durian farming alone, seeking guidance from experienced harvesters and local experts is far more efficient.

In this industry, Top Fruits Plantation stands out as the ideal mentor for your durian farming aspirations!

Established in 1986, Top Fruits has spent over three decades honing its durian growth expertise, ultimately broadening its role to offer consultancy services.

Whether you’re a newcomer in the durian farming venture or an experienced farmer seeking to diversify your portfolio, Top Fruits can transform your aspirations into reality, drawing from its expertise cultivated over years of immersion in the industry.

So why wait?

Contact Top Fruits today and become a part of Malaysia’s durian success story!

FAQ

How do you determine if a durian is ripe and ready for harvesting?

To determine if a durian is ripe, look for signs like a bulging abscission zone around the fruit stalk, the spike of the fruit turning from green to yellowish-brown in color, the spines turning pliable, carpel sutures becoming distinct, producing a dull hollow sound when tapped, and a strong, pungent aroma emitted.

What tools are commonly used for opening durians?

While a sharp knife is often sufficient to open durians, several other tools, such as specialized durian openers, machetes, cleavers, and hatchets, can also be used.

How should durians be handled and transported after harvesting to prevent damage?

Handle durians gently after harvesting to avoid bruising. Transport them in well-ventilated containers and vehicles, avoiding high heat and direct sunlight, which can accelerate ripening.

What is the proper way to clean and prepare freshly harvested durians before selling them?

Gently brush off the dirt on the durians using special brushes or air guns and remove the remaining stems attached to the fruit. Avoid washing the durians, as added moisture can speed up spoilage.

What is the proper way to clean and prepare freshly harvested durians before selling them?

What is the process of harvesting durian?

The durian harvesting process begins by identifying the ripeness of the fruits. Once deemed ready, the durians are carefully harvested by letting it drop naturally. Subsequently, the freshly harvested durians undergo a series of post-harvest steps, including in-field handling, sorting, cleaning, grading, packing, and proper storage. Finally, the processed durians are prepared for transportation to their intended destinations.